Advantages of Ultrafiltration System

1: Zero Power Requirement:

The Ultrafiltration System operates without the use of electricity. Water can be filtered using natural pressure with this technique. Choose a zero-power water purifying procedure instead of worrying about power outages or paying electricity costs.

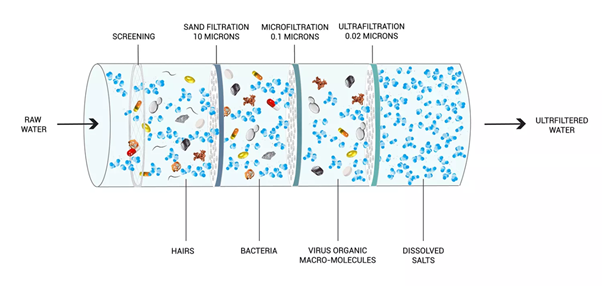

2: Viruses and bacteria are eliminated

By pushing water through a membrane, ultrafiltration eliminates particle materials. As a result, it not only kills all bacteria and viruses, but also eliminates their eggs from the water, ensuring that the water is clean and safe.

3: Deep cleaning

Even dirty muddy water may be purified with the Deep Cleaning Ultrafiltration System. In comparison to conventional filtration systems, it can readily remove all solid particle matter and germs from filthy water. The ultrafiltration membrane can quickly cleanse even the dirtiest water, making it safe to drink.

4: Ensures the purest kind of drinking water

The Ultrafiltration System will always generate safe drinking water. Because the ultrafiltration membrane is extremely robust, no small or large particle matter can flow through it.

5: System with Low Maintenance and High Performance

Water purifiers that use the Ultrafiltration System don’t need to go through a long-term maintenance routine and can last for many years. The manual flushing device in these purifiers removes all of the trapped germs and muck, ensuring that the purifier operates at peak performance for at least eleven years.

6: Excellent Purification

Most water filtration systems, with the exception of the Ultrafiltration system, use chlorine treatment to kill and extract microorganisms from the water. However, the eggs (cysts) cannot be removed with this procedure. The Ultrafiltration System, on the other hand, removes the chlorine-resistant eggs (Cysts) of gastrointestinal parasites such as cryptosporidiosis, giardiasis, and amoebic illness, resulting in pure drinkable water.