INTRODUCTION

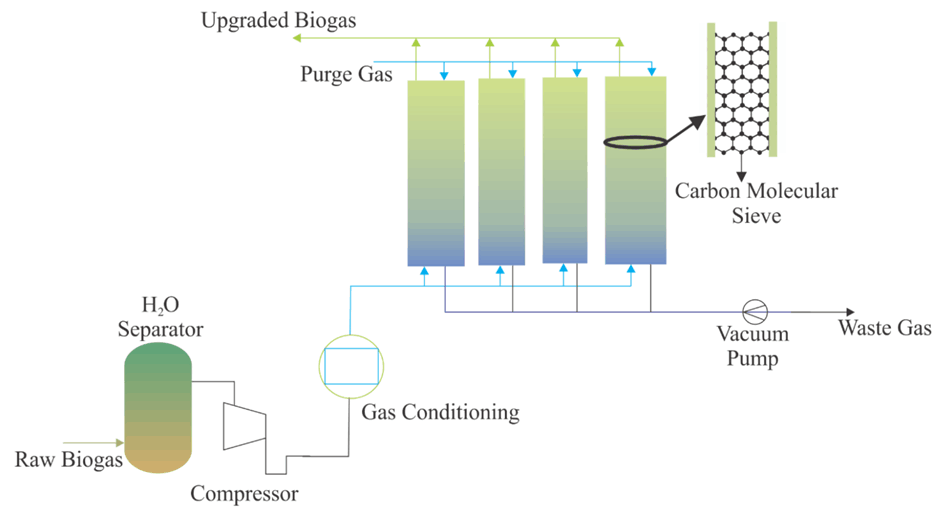

PSA (Pressure Swing Adsorption) based biogas enrichment technology is a reliable and efficient way to increase the methane content of biogas. The technology uses a series of adsorption columns filled with a proprietary adsorbent that has a strong affinity for carbon dioxide (CO2). The raw biogas is first pressurized and fed into the first adsorption column. The CO2 molecules are attracted to the surface of the adsorbent and are retained in the column, while the methane (CH4) molecules pass through the column.

Once the first adsorption column is full of CO2, the pressure is reduced. This causes the CO2 molecules to desorb from the adsorbent and be released from the column. The CH4 molecules remain in the column and are collected as the enriched biogas. The enriched biogas is then passed to the second adsorption column, where the process is repeated.