INTRODUCTION

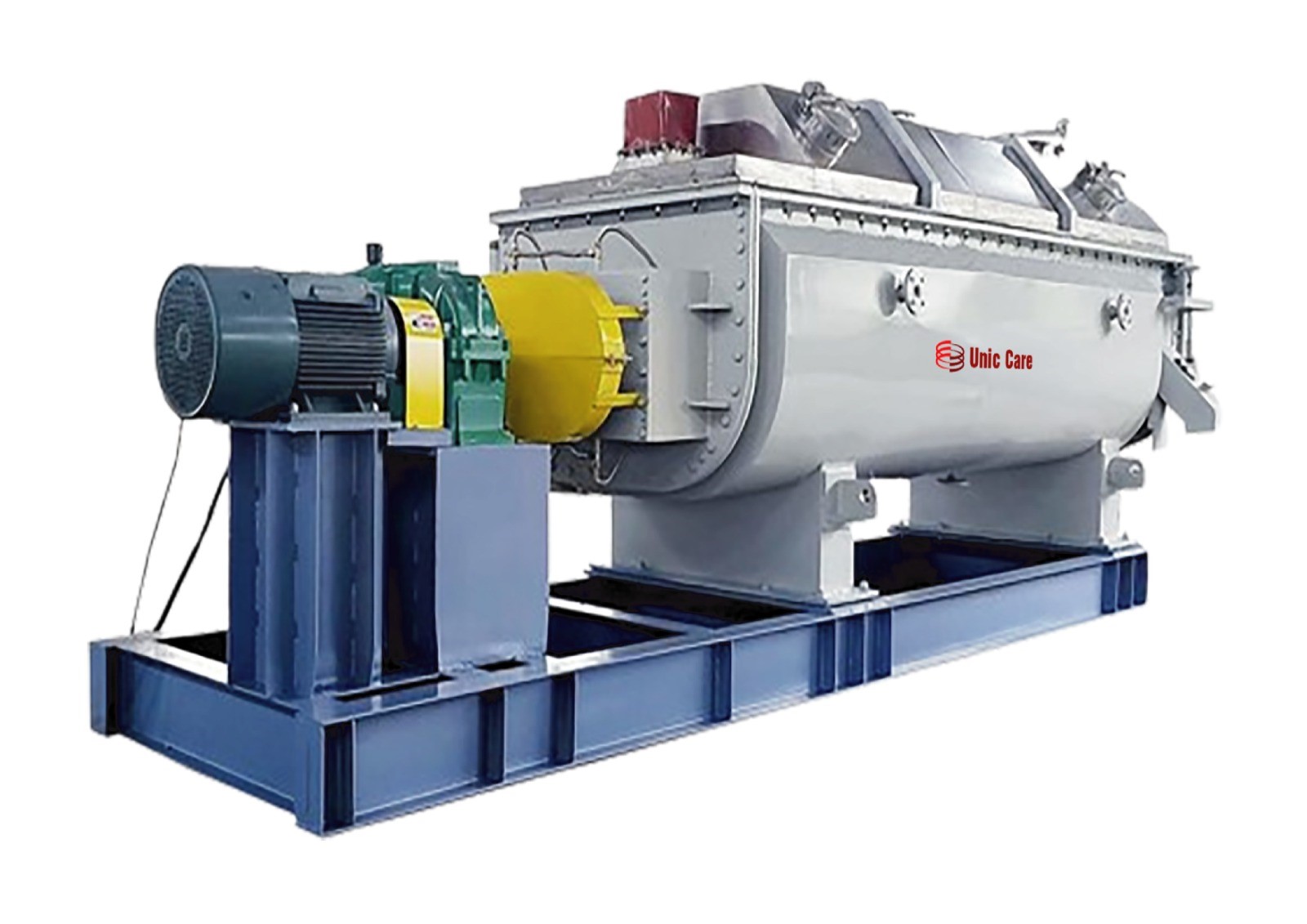

Paddle dryer is an indirect conduction heating type drying device, which is suitable for processing materials with good thermal stability such as paste, powder and granular. After special configuration, it can be used for processing heat sensitive materials, materials that need recover solvents during drying process and materials that need to be dried under rough vacuum. At the same time, paddle dryer can also be used for cooling of powder and granular materials and cooling and crystallization of some special materials by injecting cooling medium. It also can inject heating medium for heating materials and reactor to be heated.

Applicable Materials:

Widely used in chemical, mining, metallurgical and other industries, such as ore, gypsum, coal, metal powder, diatomaceous earth, kaolin, and various of sludge drying, municipal sludge, paper sludge and other drying.